As our platform is specialized in microfluidics, this pole is of particular importance. It is here that the chips will be produced in greater or lesser quantities in a dedicated clean room.

Equipment used

For the manufacture of the chip

This room has all the necessary equipment for the production of chips. It consists of two specific areas depending on the type of material used for the chip.

An area designated for the treatment of NOA,an ultraviolet curing glue (we have a 200W UV lamp). It is used for chips requiring high physical stresses or circulating solvents.

An area reserved for the handling of PDMS,the most used product for the creation of microfluidic chips. For our users, we offer two references:

- DOW Sylgard 184, the most widely used reference in scientific publications.

- RTV-615, having almost the same features but being cheaper.

Once the material is ready for use, our vacuum bells and oven make it possible to obtain a cross-linked product in less than 1 hour.

Once the PDMS is cross-linked, you can cut the material under one of the three laminar flow hoods we have. These hoods are equipped with the necessary cutting equipment for cutting and drilling.

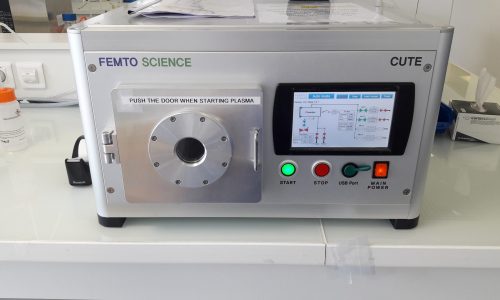

Finally, the PDMS structure will be glued to a glass slide with a plasma cleaner to obtain the microfluidic chip.

For surface treatments

In microfluidics, surface properties are of paramount importance, particularly wettability. If the latter is not high enough, it is called a hydrophobic surface. In this case, the liquids in the chip will have difficulty draining and mixing.

To make this surface hydrophobic, we have tricholoro-silane and a dedicated hood. To make it hydrophilic, oxygen plasma treatment can be useful (applies to glass and PDMS).